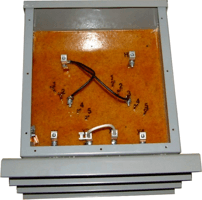

Epoxy Encapsulated Transformer.

What is an Epoxy Encapsulated Transformer?

Encapsulated Transformers are simply transformers in which one or more of the transformer's components are completely sealed. One example of a component is the transformer's coils. This process of encapsulation protects the transformer from dirt, dust, moisture, and any other contaminants. Epoxy encapsulated transformers are designed to perform in extreme environmental conditions. Epoxy Encapsulated transformers are a mixture of silica sand resin forming a solid mass completely encloses and protects the core and coil, also significantly reduces audible noise. The Enclosure is constructed from heavy gauge steel. They offer a number of advantages over traditional open-core designs. The most obvious benefits arise from the physical protection that the encapsulate and outer casing provide to the windings, core, and lead connections. With these fragile components sealed inside a tough, waterproof casing, encapsulated transformers are a clear choice whenever moisture, dust, dirt, or other environmental threats are an issue. Epoxy encapsulated is a process in which a transformer or one of its components is completely sealed with epoxy or a similar material. This process is normally preferred when a unit might encounter harsh environmental conditions. Encapsulated Transformers are designed and engineered to be protected from the most hostile environments while offering the benefit of running cooler than a comparable non-encapsulated transformer, usually rated Nema 3R or Nema 4 or above they provide reliable protection from corrosive atmospheres, hazardous gases, dust and moisture. Applications are found in pulp and paper plants, steel mills, petrochemical plants, food processing facilities, breweries, mines, marine and shipboard installation. Physical toughness and environmental ruggedness are not the only advantages. Encapsulation also has a strong impact on thermal and electrical performance. The epoxy compound used for potting has a high coefficient-of-thermal conductivity and is very effective at dissipating heat away from the windings and core. This thermal management reduces winding temperature differentials and allows the transformers to be used in higher ambient temperature environments without exceeding allowable temperatures for the insulation class. The epoxy encapsulated also increases electrical insulation reliability when compared to tape or paper insulation. All production is subjected to a 4,000V hi-pot test between primary and secondary windings. With no air around the windings, there is reduced potential for corona under high voltage surge conditions. The epoxy also serves to reduce operational noise significantly. Other benefits of Encapsulated Transformers include the following Encapsulated Transformers:

- Able to withstand the harshest environmental conditions with a tough, sealed, waterproof encasement.

- High thermal conductivity.

- Dissipates heat away from the core and windings.

- Outstanding performance in environments with high ambient temperatures.

- Extremely reliable electrical insulation.

- Reduction of corona possibility in high surge situations.

- Stringent testing of 4,000 hi-pot between primary and secondary windings.

- ❮Go back to the previous page.

- Use the search bar at the top of the page to search for your products.

- Follow these links to get you back on track!

Store Home | My Account

The manufacturing process for encapsulated power transformers is highly automated and closely controlled for quality and consistency. Potting is done under vacuum. All products are thoroughly tested at each stage and are designed to meet a wide range of Canadian, US and international standards. Given their mechanical ruggedness and electrical and thermal characteristics, encapsulated transformers can be used for a wide range of challenging applications, including industrial equipment or appliances designed for harsh operating conditions, out-door metering equipment, and line-monitoring electronics. Epoxy Encapsulated transformers are available in Dry type Transformers, Step-up and Step-down transformers, isolation transformers, and K-Factor Transformers.

United States

United States