Single Phase, Three Phase Transformers

Single Phase Transformers

Single-phase distribution is used when loads are mostly lighting and heating, with few large electric motors. In electrical engineering, single-phase electric power refers to the distribution of electric power using a system in which all the voltages of the supply vary in unison. A single-phase load may be powered from a three-phase distribution system either by connection between a phase and neutral or by connecting the load between two phases. Single-phase loads may be connected to a three-phase system, either by a phase-to-phase connection, or by connecting between a phase conductor and the system neutral, which is either connected to the center of the Y (star) secondary winding of the supply transformer, or is connected to the center of one winding of a delta transformer. Single-phase loads should be distributed evenly between the phases of the three-phase system for efficient use of the supply transformer and supply conductors. The line-to-line voltage of a three-phase system is 3 times the line to neutral voltage. Where the line-to-neutral voltage is a standard utilization voltage, individual single-phase utility customers or loads may each be connected to a different phase of the supply. Where the line-to-neutral voltage is not a common utilization voltage, single-phase loads must be supplied by individual step-down transformers. In multiple-unit residential buildings in Canada, lighting and convenience outlets can be connected line-to-neutral to give the 120 V distribution voltage (115V utilization voltage), and high-power loads such as cooking equipment, space heating, water heaters, or air conditioning can be connected across two phases to give 208 V. This practice is common enough that 208 V single-phase equipment is readily available in North America. Attempts to use the more common 120/240 V equipment intended for three-wire single-phase distribution may result in poor performance since 240 V heating equipment will only produce 75% of its rating when operated at 208 V. No arrangement of transformers can convert a single-phase load into a balanced load on a three phase system. Single-phase power distribution is used especially in rural areas, where the cost of a three-phase distribution network is high and motor loads are small and uncommon. Two phase power, meaning the simultaneous provision of sine wave and cosine wave electricity (that is, 90 degrees out of phase) is no longer widely used. But sometimes it is incorrectly described split single phase services as "two phase", when in fact such services are really still single phase power. Single-phase electric power refers to the distribution of electric power using a system in which all the voltages of the supply vary in unison. Single-phase distribution is used when loads are mostly lighting and heating, with few large electric motors. Single-phase power distribution is used especially in rural areas, where the cost of a three-phase distribution network is high and motor loads are small and uncommon. High power systems are nearly always three phase. But the largest supply normally available as single phase varies considerably by country and in some cases region. In North America, individual residences and small commercial buildings with services up to about 100 kV·A (400 amperes at 240 volts) will usually have three-wire single-phase distribution, often with only one customer per distribution transformer. Larger consumers such as large buildings, shopping centers, factories, office blocks, and multiple-unit apartment blocks will have three-phase service. In densely-populated areas of cities, network power distribution is used with many customers and many supply transformers connected to provide hundreds or thousands of kVA load concentrated over a few hundred square meters. A single-phase supply connected to a pure single-phase induction motor does not produce a revolving magnetic field, and so practical single-phase motors always have some means of producing a revolving field to generate starting torque. Aside from certain traction power applications, single-phase induction motors greater than 10 or 20 kW are very uncommon. Normally , when three-phase is required, a single enclosure with three primary and three secondary windings wound on a common core is all that is required. However three single-phase transformers with the same rating can be connected to form a three-phase bank. Since each single-phase transformer has a primary and a secondary winding, then 3 single-phase transformers will have the required 3 primary and 3 secondary windings and can be connected in the field either Delta-Delta or Delta-Wye to achieve the required three-phased transformer bank.

Single-phase distribution is used when loads are mostly lighting and heating, with few large electric motors. In electrical engineering, single-phase electric power refers to the distribution of electric power using a system in which all the voltages of the supply vary in unison. A single-phase load may be powered from a three-phase distribution system either by connection between a phase and neutral or by connecting the load between two phases. Single-phase loads may be connected to a three-phase system, either by a phase-to-phase connection, or by connecting between a phase conductor and the system neutral, which is either connected to the center of the Y (star) secondary winding of the supply transformer, or is connected to the center of one winding of a delta transformer. Single-phase loads should be distributed evenly between the phases of the three-phase system for efficient use of the supply transformer and supply conductors. The line-to-line voltage of a three-phase system is 3 times the line to neutral voltage. Where the line-to-neutral voltage is a standard utilization voltage, individual single-phase utility customers or loads may each be connected to a different phase of the supply. Where the line-to-neutral voltage is not a common utilization voltage, single-phase loads must be supplied by individual step-down transformers. In multiple-unit residential buildings in Canada, lighting and convenience outlets can be connected line-to-neutral to give the 120 V distribution voltage (115V utilization voltage), and high-power loads such as cooking equipment, space heating, water heaters, or air conditioning can be connected across two phases to give 208 V. This practice is common enough that 208 V single-phase equipment is readily available in North America. Attempts to use the more common 120/240 V equipment intended for three-wire single-phase distribution may result in poor performance since 240 V heating equipment will only produce 75% of its rating when operated at 208 V. No arrangement of transformers can convert a single-phase load into a balanced load on a three phase system. Single-phase power distribution is used especially in rural areas, where the cost of a three-phase distribution network is high and motor loads are small and uncommon. Two phase power, meaning the simultaneous provision of sine wave and cosine wave electricity (that is, 90 degrees out of phase) is no longer widely used. But sometimes it is incorrectly described split single phase services as "two phase", when in fact such services are really still single phase power. Single-phase electric power refers to the distribution of electric power using a system in which all the voltages of the supply vary in unison. Single-phase distribution is used when loads are mostly lighting and heating, with few large electric motors. Single-phase power distribution is used especially in rural areas, where the cost of a three-phase distribution network is high and motor loads are small and uncommon. High power systems are nearly always three phase. But the largest supply normally available as single phase varies considerably by country and in some cases region. In North America, individual residences and small commercial buildings with services up to about 100 kV·A (400 amperes at 240 volts) will usually have three-wire single-phase distribution, often with only one customer per distribution transformer. Larger consumers such as large buildings, shopping centers, factories, office blocks, and multiple-unit apartment blocks will have three-phase service. In densely-populated areas of cities, network power distribution is used with many customers and many supply transformers connected to provide hundreds or thousands of kVA load concentrated over a few hundred square meters. A single-phase supply connected to a pure single-phase induction motor does not produce a revolving magnetic field, and so practical single-phase motors always have some means of producing a revolving field to generate starting torque. Aside from certain traction power applications, single-phase induction motors greater than 10 or 20 kW are very uncommon. Normally , when three-phase is required, a single enclosure with three primary and three secondary windings wound on a common core is all that is required. However three single-phase transformers with the same rating can be connected to form a three-phase bank. Since each single-phase transformer has a primary and a secondary winding, then 3 single-phase transformers will have the required 3 primary and 3 secondary windings and can be connected in the field either Delta-Delta or Delta-Wye to achieve the required three-phased transformer bank.

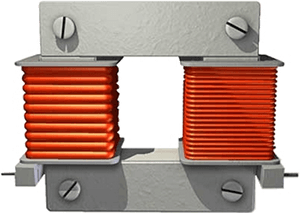

Configuration for Single Phase Transformer.

Single-phase transformers are often used to supply power for residential lighting, receptacle, air-conditioning, and heating needs. A transformer with a 120 volt AC secondary can take care of the lighting and receptacles. But, a transformer with a 240 volt AC secondary could handle all the residential needs mentioned. A 240 volt AC secondary could handle the heavier 240 volt power requirements of air conditioning and heating. The same 240 volt AC secondary could handle the 120 volt AC needs by tapping the secondary in the center. Single phase transformers can be made even more versatile by having both the primary winding and secondary winding made in two equal parts. The two parts of either winding can then be reconnected in series or parallel configurations.

Series Configuration Parallel Configuration.

Single-phase transformers usually have their windings divided into two or more sections. When the two secondary windings are connected in series, their voltage is added. When the secondary windings are connected in parallel, their currents are added. For example, assume each secondary winding is rated at 120 volts and 100 amps. When series-connected, it would be 240 volts at 100 amps, or 24KVA. When parallel-connected, it would be 120 volts at 200 amps, or 24KVA. In series connections, care must be taken to connect the coils so that their voltages add. If the reverse happens, a short-circuit current would flow in the secondary, causing the primary to draw a short circuit from the source. This would damage the transformer, as well as the source, and perhaps the connector.

Three Phase Power

Three-phase is a common method of electric power transmission. It is a type of system used to power motors and many other devices. Three phase systems may or may not have a neutral wire. A neutral wire allows the three phase system to use a higher voltage while still supporting lower voltage single phase appliances. In high voltage distribution situations it is common not to have a neutral wire as the loads can simply be connected between phases - phase-to-phase connection. Three phase has properties that make it very desirable in electric power systems. Firstly the phase currents tend to cancel one another (summing to zero in the case of a linear balanced load). This makes it possible to eliminate the neutral conductor on some lines. Secondly power transfer into a linear balanced load is constant, which helps to reduce generator and motor vibrations. Finally, three-phase systems can produce a magnetic field that rotates in a specified direction, which simplifies the design of electric motors. Three is the lowest phase order to exhibit all of these properties. Most domestic loads are single phase. Generally three phase power either does not enter domestic houses at all, or where it does, it is split out at the main distribution board. The three phases are typically indicated by colors which vary by country. Occasionally the advantages of three-phase motors make it worthwhile to convert single-phase power to three phase. Small customers, such as residential or farm properties may not have access to a three-phase supply, or may not want to pay for the extra cost of a three-phase service, but may still wish to use three-phase equipment. Such converters may also allow the frequency to be varied allowing speed control. Some locomotives are moving to multi-phase motors driven by such systems even though the incoming supply to a locomotive is nearly always either DC or single phase AC. Because single-phase power is interrupted at each moment that the voltage crosses zero but three-phase delivers power continuously, any such converter must have a way to store energy for the necessary fraction of a second. One way for using three-phase equipment on a single-phase supply is with a rotary phase converter, essentially a three-phase motor with special starting arrangements and power factor correction that produces balanced three-phase power. When properly designed these rotary converters can allow satisfactory operation of three-phase equipment such as machine tools on a single phase supply. In such a device, the energy storage is performed by the mechanical inertia (flywheel effect) of the rotating components.

Three-phase is a common method of electric power transmission. It is a type of system used to power motors and many other devices. Three phase systems may or may not have a neutral wire. A neutral wire allows the three phase system to use a higher voltage while still supporting lower voltage single phase appliances. In high voltage distribution situations it is common not to have a neutral wire as the loads can simply be connected between phases - phase-to-phase connection. Three phase has properties that make it very desirable in electric power systems. Firstly the phase currents tend to cancel one another (summing to zero in the case of a linear balanced load). This makes it possible to eliminate the neutral conductor on some lines. Secondly power transfer into a linear balanced load is constant, which helps to reduce generator and motor vibrations. Finally, three-phase systems can produce a magnetic field that rotates in a specified direction, which simplifies the design of electric motors. Three is the lowest phase order to exhibit all of these properties. Most domestic loads are single phase. Generally three phase power either does not enter domestic houses at all, or where it does, it is split out at the main distribution board. The three phases are typically indicated by colors which vary by country. Occasionally the advantages of three-phase motors make it worthwhile to convert single-phase power to three phase. Small customers, such as residential or farm properties may not have access to a three-phase supply, or may not want to pay for the extra cost of a three-phase service, but may still wish to use three-phase equipment. Such converters may also allow the frequency to be varied allowing speed control. Some locomotives are moving to multi-phase motors driven by such systems even though the incoming supply to a locomotive is nearly always either DC or single phase AC. Because single-phase power is interrupted at each moment that the voltage crosses zero but three-phase delivers power continuously, any such converter must have a way to store energy for the necessary fraction of a second. One way for using three-phase equipment on a single-phase supply is with a rotary phase converter, essentially a three-phase motor with special starting arrangements and power factor correction that produces balanced three-phase power. When properly designed these rotary converters can allow satisfactory operation of three-phase equipment such as machine tools on a single phase supply. In such a device, the energy storage is performed by the mechanical inertia (flywheel effect) of the rotating components.

What is Three Phase Transformer?

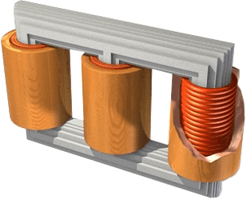

A three phase transformer is a three-legged iron core. Each leg has a respective primary and secondary winding. Most power is dispersed in the form of three-phase AC. Basically the power company generators produce electricity by rotating 3 coils or windings through a magnetic field within the generator. These coils or windings are spaced 120 degrees apart. As they rotate through the magnetic field they generate power which is then sent out on three lines as in three-phase power. A three phase transformers must have 3 coils or windings connected in the proper sequence in order to match the incoming power and therefore transform the power company voltage to the level of voltage we need and maintain the proper phasing or polarity. Three phase transformers is a common and popular method for electric power transmission. There are many benefits to three phase power:

- All three wires can carry the same current.

- Power transfer is constant into a linear and balanced load.

Three Phase Transformer Construction:

A three phase transformer is constructed by winding three single phase transformers on a single core. These transformers are put into an enclosure which is then filled with dielectric oil. Since it is a dielectric, a nonconductor of electricity, it provides electrical insulation between the windings and the case. It also used to help provide cooling and to prevent the formation of moisture, which can deteriorate the winding insulation. There are only 4 possible transformer combinations:

- Delta to Delta - use: industrial application

- Delta to Wye - use: most common, commercial and industrial

- Wye to Delta - use: high voltage transmissions

- Wye to Wye - use: rare, causes harmonics and balancing problems.

Three phase transformers are connected in delta or wye configurations. A wye-delta transformer has its primary winding connected in a wye and its secondary winding connected in a delta. A delta-wye transformer has its primary winding connected in delta and its secondary winding connected in a wye.

Delta Connections:

A delta system is a good short-distance distribution system. Applications of these transformers are usually found in neighborhood and small commercial loads close to the supplying substation. Only one voltage is available between any two wires in a delta system. The delta system can be illustrated by a simple triangle. A wire from each point of the triangle would represent a three-phase, three-wire delta system, the voltage would be the same between any two wires.

Wye Connections:

In a wye system the voltage between any two wires will always give the same amount of voltage on a three phase systems. However the voltage between any one of the phase conductors and the the neutral will be less than the power conductors. For example, if the voltage between the power conductors of any two phases of a three wire system is 208v, then the voltage from any phase conductor to ground will be 12-v. This is due to the square root of three phase power. In a wye system, the voltage between any two power conductors will always be 1.732 (which is the square root of 3) times the voltage between the neutral and any one of the power phase conductors. The phase-to-ground voltage can be found by dividing the phase-to-phase voltage by 1.732.

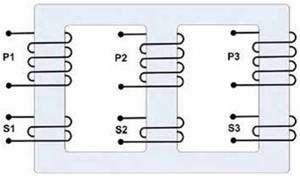

Single-phase transformers in a three phase bank:

When you have a three phase transformer and it is not available in the proper size or turns ratio a three phase conversion is needed. Single phase transformers can be connected to form a three phase bank. When three single phase transformers are used to make a three phase transformer bank, their primary and secondary windings are connected in a wye or delta connection.

Open Delta Connection:

The open delta transformer connection can be made with only two transformers instead of three. Usually the delta transformer are used in small business where the three phase transformer would be excessive. It should be noted that the output power of an open delta connection is only 87% of the rated power of the two transformers. The voltage and current values of an open delta connection are computed in the same manner as a standard delta-delta connection when three transformers are used. The voltage and current rules for a delta connection must be used when determining line and phase values of voltage current.

- Go back to the previous page.

- Use the search bar at the top of the page to search for your products.

- Follow these links to get you back on track!

Store Home | My Account

United States

United States