Autotransformer.

What is Autotransformer.

Autotransformer (Auto-Transformer) is an electrical transformer in which there is one winding, a portion of which is common to both the primary and the secondary circuits. An autotransformer uses common winding and offer no interference or disturbance isolation. The current in the high-voltage circuit flows through the series and common winding. The current in the low-voltage circuit flows through the common winding and adds vectorially to the current in the high-voltage circuit to give the common winding current. The principle difference between an autotransformer and an isolation transformer is the separation of the secondary windings. Because the auto-transformer uses a single coil winding for both the primary input and the secondary output, any electrical noise, voltage spikes, sags or any other undesirable condition will pass through unchecked. Equipment susceptible to damage by poor line conditions will not be protected. And noise and harmonics generated by components on the secondary side will be allowed to transmit onto the main supply line. Because the auto-transformer can transmit line disturbances directly, local building codes may prohibit their use in certain areas. Auto-Transformers also should not be used in closed delta connections as they will introduce into the circuit a phase shift which causes higher power use.

Autotransformer (Auto-Transformer) is an electrical transformer in which there is one winding, a portion of which is common to both the primary and the secondary circuits. An autotransformer uses common winding and offer no interference or disturbance isolation. The current in the high-voltage circuit flows through the series and common winding. The current in the low-voltage circuit flows through the common winding and adds vectorially to the current in the high-voltage circuit to give the common winding current. The principle difference between an autotransformer and an isolation transformer is the separation of the secondary windings. Because the auto-transformer uses a single coil winding for both the primary input and the secondary output, any electrical noise, voltage spikes, sags or any other undesirable condition will pass through unchecked. Equipment susceptible to damage by poor line conditions will not be protected. And noise and harmonics generated by components on the secondary side will be allowed to transmit onto the main supply line. Because the auto-transformer can transmit line disturbances directly, local building codes may prohibit their use in certain areas. Auto-Transformers also should not be used in closed delta connections as they will introduce into the circuit a phase shift which causes higher power use.

Autotransformer Construction

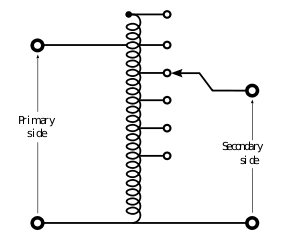

Construction is characterized by a single copper wire coil common to both the primary and secondary circuits, wound around a silicone steel core. While theoretically separate parts of the winding can be used for input and output, in practice the higher voltage will be connected to the ends of the winding, and the lower voltage from one end to a tap. For example, a transformer with a tap at the center of the winding can be used with 230 volts across the entire winding, and 115 volt equipment, or reversed to drive 230 volts equipment from 115 volts. As the same winding is used for input and output, the flux in the core is partially cancelled, and a smaller core can be used. For voltage ratios not exceeding about 3:1, auto transformer is cheaper, lighter, smaller and more efficient than a true (two-winding) transformer of the same rating. By exposing part of the winding coils and making the secondary connection through a sliding brush, an auto transformer with a near-continuously variable turns ratio can be obtained, allowing for very small increments of voltage. Auto Transformers vs. Isolation Transformers Physically smaller and more economical to purchase, the auto-transformer can be an attractive alternative to an equivalently rated isolation transformer, under the correct conditions.

Construction is characterized by a single copper wire coil common to both the primary and secondary circuits, wound around a silicone steel core. While theoretically separate parts of the winding can be used for input and output, in practice the higher voltage will be connected to the ends of the winding, and the lower voltage from one end to a tap. For example, a transformer with a tap at the center of the winding can be used with 230 volts across the entire winding, and 115 volt equipment, or reversed to drive 230 volts equipment from 115 volts. As the same winding is used for input and output, the flux in the core is partially cancelled, and a smaller core can be used. For voltage ratios not exceeding about 3:1, auto transformer is cheaper, lighter, smaller and more efficient than a true (two-winding) transformer of the same rating. By exposing part of the winding coils and making the secondary connection through a sliding brush, an auto transformer with a near-continuously variable turns ratio can be obtained, allowing for very small increments of voltage. Auto Transformers vs. Isolation Transformers Physically smaller and more economical to purchase, the auto-transformer can be an attractive alternative to an equivalently rated isolation transformer, under the correct conditions.

Autotransformer Applications

Autotransformers are primarily used to either step up or step down single or three phase line voltages to desired levels. Autotransformers are best used in applications where the line voltage needs to be matched to a protected piece of equipment. A good example would be a machine tool which was manufactured in Europe and designed to operate on 400V. The drives and controls within the machine would be protected by either inductors or transformers already installed in the machine tool. An isolation transformer could convert a 480 supply voltage to 400V but the additional isolation would be redundant and expensive. An auto-transformer would perform the voltage conversion for a fraction of the cost of the isolation transformer, in a package which would be approximately two thirds smaller.

- ❮Go back to the previous page.

- Use the search bar at the top of the page to search for your products.

- Follow these links to get you back on track!

Store Home | My Account

United States

United States