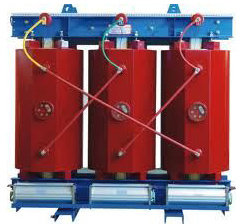

Dry type Transformer.

What is a Dry type Transformer?

Dry type transformers require minimum maintenance to provide many years of reliable trouble free service. A dry-type transformer has no moving parts and is a completely static solid state device, under normal operating conditions, are usually insure a long and trouble-free life. Unlike liquid fill transformers which are cooled with oil or fire resistant liquid dielectric, dry type units utilize only environmentally safe, CSA and UL recognized high temperature insulation systems. Dry type transformers provide a safe and reliable power source which does not require fire proof vaults, catch basins or the venting of toxic gasses. These important safety factors allow the installation of dry type transformers inside buildings close to the load, which improves overall system regulation and reduces costly secondary line losses.

Fire-resistant dry type or "cast resin" transformers are well suited for installation in high-rise buildings, hospitals, underground tunnels, school, steel factories, chemical plants and places where fire safety is a great concern. Hazard free to the environment, dry type transformers have over the years proven to be highly reliable. “Dry type” simply means it is cooled by normal air ventilation. The dry type transformer does not require a liquid such as oil or silicone or any other liquid to cool the electrical core and coils. Dry type transformers are voltage changing (Step-up or Step-down) or isolation device that is air cooled rather than liquid cooled. The transformer case is ventilated to allow air to flow and cool the coil (coils).

Dry type transformers differ from liquid-filled units in many ways, and separate industry standards apply to their design, construction, and maintenance. Dry-Type Transformers suitable for indoor and outdoor applications anywhere that safe and dependable power are important. Cooling ducts in the windings allow heat to be dissipated into the air. Dry-types can operate indoors under almost all ambient conditions for commercial buildings and light manufacturing facilities. For outdoor operations, a dry-type transformer's enclosure will usually have louvers for ventilation. But, these transformers can be affected by hostile environments (dirt, moisture, corrosive fumes, conductive dust, etc.) because the windings are exposed to the air. Other approaches to building dry-type transformers for harsh environments include cast coil units, cast resin units, and vacuum pressure encapsulated (VPE) units, sometimes using a silicone varnish. Unless the dry-type units are completely sealed, the core/coil and lead assemblies should be periodically cleaned, even in non-harsh environments, to prevent dust and other contaminant buildup over time.

Type of Dry Type Transformers:

There are several different construction methods used in manufacturing dry type transformers. Each of these different types is suited for particular environments or applications. If you are looking for corona protection and increased mechanical strength a VPI dry type transformer would be your best options. But, if you are in a harsh environment a cast coil transformer may be your answer.

Dry Type Transformers - Open Wound Transformer

These transformers are construction with a dip-and bake method. It is accomplished by preheating the conductor oils and then heated, dipping them in varnish at an elevated temperature. The coils are then baked to cure the varnish.

Dry Type Transformers - Vacuum Pressure Impregnated (VPI)

The VPI transformers are construction with high-temperature insulation that exceeds the rating of cellulose or 'O' and 'K' class fluids. They are comprised of high-temperature materials coated with high-temperature, moisture-resistant polyester sealant. The polyester sealant is typically applied with a vacuum pressure impregnation process. They are used in diverse commercial and industrial environments for decades. They are generally rated up to 30 MVA.

Dry Type Transformers - Vacuum Pressure Encapsulated (VPE)

The VPE dry type transformers are similar to VPI transformers, but employ a resin made of silicone instead of polyester. The VPE includes several dip processes to encapsulate the coil assembly and then the coating is cured in an oven. The resin coating is thicker, sometimes by as much as a factor of four. VPE transformers are highly resistant to humid and caustic environments. These VPE are ideal for harsh environments such as acids, alkalis and chlorides. They are also resistant to the the effects of salt water and high humidity.

Dry Type Transformers - Cast Coil

In the cast coil design, the coils are solidly cast in resin under a vacuum in a mold. Winding processes controlled by advanced electronics also ensure even distribution and high level of precision. The cast coil transformers are reliable, have a high short circuit withstands, and can be exposed to extreme conditions with minimal maintenance. They are used inside buildings and tunnels, on ships, offshore platforms and cranes, food-processing plant, nuclear plants and mining industry.

Quality Dry Type Transformers

Dry-type transformers can have their windings insulated various ways. A basic method is to preheat the conductor coils and then, when heated, dip them in varnish at a high temperature. The coils are then baked to cure the varnish. This process is an open-wound method and helps ensure penetration of the varnish. Cooling ducts in the windings provide an efficient and economical way to remove the heat produced by the electrical losses of the transformer by allowing air to flow through the duct openings. This dry-type insulation system operates satisfactorily in most ambient conditions are also sealed with an epoxy resin mixture. Another version of the dry-type transformer is a cast coil insulation system. It is used when addition coil strength and protection are advisable. Theses type of transformer are used in located where environments are harsh, such as cement and chemical plants and outdoor installations where moisture, salt spray, corrosive fumes, dust, and metal particles can destroy other types of dry-type transformers. These cast coil units are better able to withstand heavy power surges, such as frequent but brief overloads experienced by transformers serving transit systems and various industrial machinery. Cast coil units are now being used where previously only liquid-filled units were available for harsh environments. They can have the same high levels of BIL while still providing ample protection of the coils and the leads going to the terminals. Dry-type transformer according to ANSI/EEE C57.96-1989 that you can have a 20-yr life expectancy for the insulation system in a transformer. For dry-type transformers having a 220°C, insulating system and a winding hot-spot temperature of 220°C, and with no unusual operating conditions present, the 20 yr life expectancy is a reasonable time fame. However, due to degradation of the insulation, a transformer might fail before 20 years. Most 150°C rise dry-type transformers are build with 220°C insulation systems. Operating such a transformer at rated kVA on a continuous basis with a 30°C average ambient should equate to a "normal" useful life. The life of a transformer increases appreciably if the operating temperature is lower than the maximum temperature rating of the insulation. However, you should recognize that the life expectancy of transformers operating at varying temperatures is not accurately known. Fluctuating load conditions and changes in ambient temperature make it difficult, if not impossible, to arrive at such definitive information.

Dry type Transformers - Classes of insulation

Dry-type transformers are available in three general classes of insulation. The main features of insulation are to provide dielectric strength and to be be able to withstand certain thermal limits. Insulation classes are:

- 220°C (Class R).

- 180°C (Class H),

- 155°C (Class F).

- 130°C (Class B).

- 105°C (Class A).

Temperature rise ratings are based on full-load rise over ambient (usually 40°C above ambient and are 150°C (available only with Class H insulation), 115°C (available with Class H and Class F insulation) and 80°C (available with Class H, F, and B insulation). A 30°C winding hot spot allowance is provided for each class. The lower temperature rise transformers are more efficient, particularly at loadings of 50% and higher. Full load losses for 115 °C transformers are about 30% less that those of 150°C transformers. And 80°C transformers have losses that are about 15% less than 115°C transformers and 40% less than 150°C transformers. Full load losses for 150°C transformers range from about 4% to 5% to 30 kVA and smaller to 2% for 500 kVA and larger. When operated continuously at 65% or more of full load, the 115°C transformer will pay for itself over the 150°C transformer in 2 yrs or less( 1 yr. if operated at 90% of full load). the 80°C transformer requires operation at 75% or more of full load for a 2-yr payback, and at 100% load to payback in 1 yr over the 150°C transformer. If operated continuously at 80% or more of full load, the 80°C transformer will have a payback over the 115°C transformer in 2 yrs or less. You should note that at loadings below 50% of full load, there is essentially no payback for either the 115°C or the 80°C transformer over the 150°C transformer, Also at loadings below 40% the lower temperature rise transformers become less efficient that the 150°C transformers. Thus, not only is there no payback, but also the annual operating cost is higher.

- Go back to the previous page.

- Use the search bar at the top of the page to search for your products.

- Follow these links to get you back on track!

Store Home | My Account

United States

United States